Material lightweighting is an important measure in the automotive industry to reduce energy consumption and emissions. Reducing the weight of parts can effectively decrease the fuel consumption of vehicles. Statistics show that for every 10% reduction in the vehicle’s own weight, fuel consumption can be reduced by 6%-8%.

In the vigorous development of new energy vehicles, material lightweighting has an even more urgent demand. Vehicles with lower mass have a longer driving range. Automotive parts have widely adopted SMC materials instead of steel, and many automotive parts can be made with SMC sheet molding compound, such as: dashboards, roofs, floors, doors, spoilers, sunshades, trunk lids, engine hoods, etc.

The application of hollow glass microspheres in composite materials can further reduce the weight of materials. Hollow glass microspheres are micron-level smooth surface hollow glass microspheres, mainly composed of alkali-lime borosilicate glass, with characteristics such as high-temperature resistance, low thermal conductivity, electrical insulation, low density, and sound insulation and noise reduction. Adding hollow glass microspheres to the SMC formula can effectively reduce the density of the material, thereby reducing the weight of the molded parts and achieving lightweighting of parts and the vehicle body.

Application Case

SMC Composite Material Battery Housing

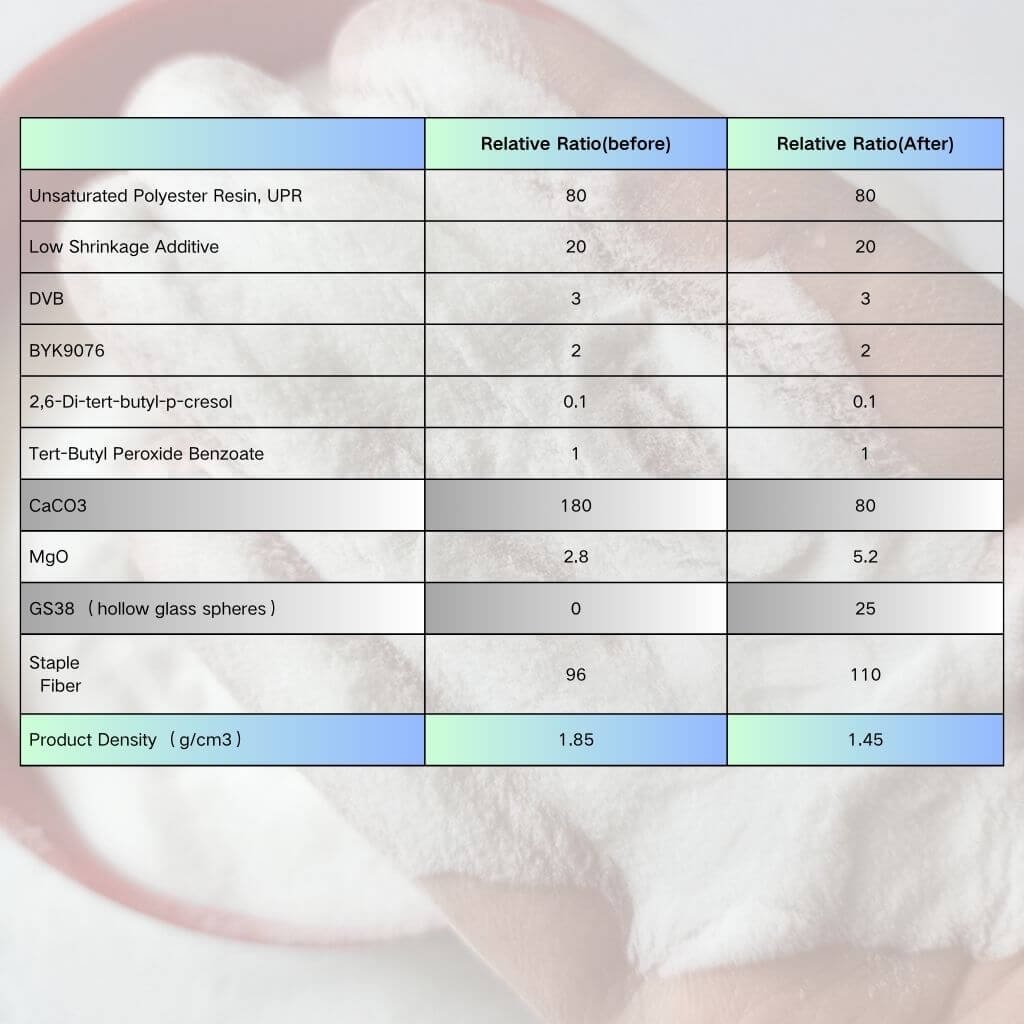

In the SMC formula, replacing calcium carbonate (CaCO3) with hollow glass microspheres can reduce the density of sheet molding compound (SMC) from the traditional ‘Class A’ formula of 1.85 g/cm³ to approximately 1.30 g/cm³ (a reduction of about 30%), while maintaining good surface quality and mechanical properties, allowing for the production of lighter components. One formulation for the application of hollow glass microspheres in SMC is as follows:

Points for Attention

- Thickener: Since hollow glass microspheres are spherical particles, they contribute to improving the fluidity of the resin system, and it is possible to consider appropriately increasing the amount of thickener in the SMC formula system.

- Selection of hollow glass microspheres: It is important to choose hollow glass microspheres with an appropriate particle size; particles that are too large can affect the surface glossiness.