Ultrafiltration (UF) is an essential process in water treatment, pharmaceuticals, food processing, and many other industries where the separation of macromolecules from smaller solutes is required. One of the key components in enhancing the performance of UF membranes is the use of polyvinylpyrrolidone (PVP) as a pore-forming agent. This article explores the role of PVP in UF membranes and highlights its advantages.

What is PVP?

PVP is a non-ionic, water-soluble polymer that possesses both hydrophilic and hydrophobic groups within its molecular structure. These dual characteristics enable it to dissolve not only in water but also in a wide range of organic solvents. PVP’s low toxicity and good physiological compatibility make it ideal for various applications, including as a pore-forming agent in membrane technology.

How Does PVP Function in UF Membranes?

When used as a pore-former, PVP is incorporated into the casting solution of the UF membrane during manufacture. The addition of PVP affects the phase inversion process, which is a common method for creating UF membranes. During this process, the polymer solution undergoes a change in thermodynamic state, leading to phase separation and the formation of a three-dimensional polymer network. As the membrane comes into contact with water, the PVP dissolves, creating channels that facilitate the formation of finger-like pores. This mechanism allows for the creation of a membrane with high porosity and a well-defined structure.

notes:

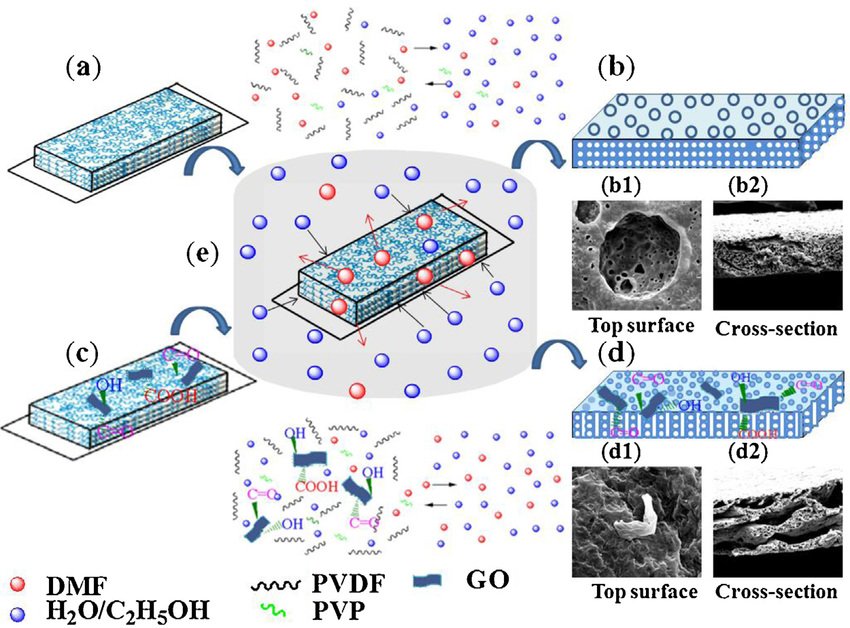

Schematic representation showing the different formation mechanisms for the PVDF/PVP membrane and PVDF/PVP/GO composite membranes. (a) Solution of PVDF/PVP, (b) porous PVDF/PVP membrane, (c) solution of PVDF/PVP/GO, (d) porous PVDF/PVP/GO composite membrane, and (e) the process relating to the exchange of the solvent (DMF) in PVDF solution with the non-solvent (water and ethanol) from the coagulation bath. (b1, b2) and (d1, d2) exhibit the corresponding morphology of the PVDF/PVP and PVDF/PVP/GO membranes, respectively.