Appearance and Characteristics: Transparent colorless or yellowish liquid with a slight odor at normal temperature. Its melting point is 14 °C. NVP is easily soluble in water or various organic solvents. It is reactive and susceptible to polymerizing or hydrolyzing.

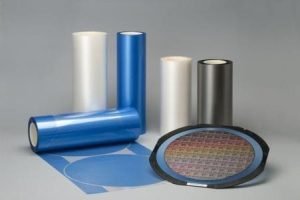

Usage And Application: NVP Monomer for UV-Curable Coatings in Plastics, Electronics, and Metal Industries

Plastic industry: NVP can be added into UV-curing coating to form a flexible and hard film. NVP can improve the elongation and viscosity of high and low gloss coating in radiation medicine

Electronic industry: Wiring manufacturers rely on rapid processes and low-temperature

processes of UV coating to protect cables, electrical components, and print-circuit boards.

Metal industry: Cationic vinyl ether epoxies or heterocyclic compounds are often used in UV coating for metal. It is the function of NVP to form excellent diluents by cross-linking with groups of such vinyl ether and acrylic acids in these systems. Other industries: NVP can be widely used in lumbering, paper-marking, inks and adhesives, etc.

Others

NVP monomers have a wide range of applications in various industrial fields such as wood, papermaking, ink, adhesives, and more.

Packing and Storage

1. 1KG, 5KG, 25KG, 200KG drums;

2. Store in sealed, light-proof, low-temperature, and neutral or slightly alkaline conditions;

3. Add inhibitors such as NaOH or ammonia water during storage and transportation.